Years of

Experience

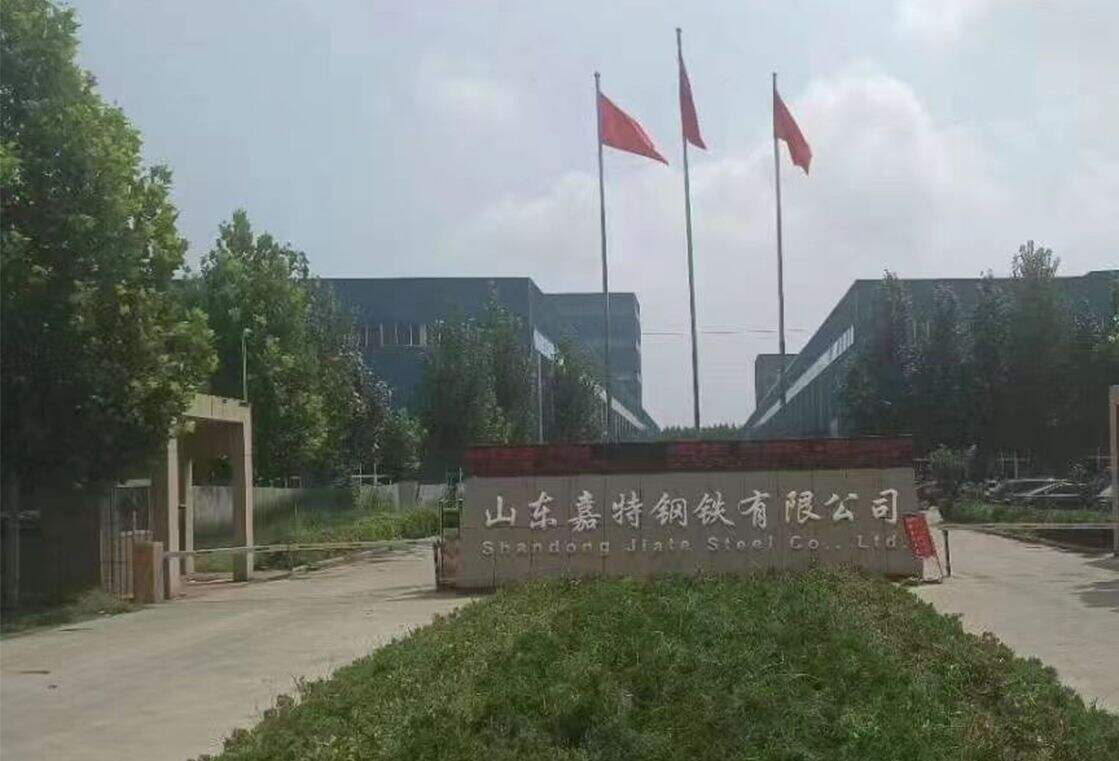

Shandong Jiate Steel Co.,Ltd. is an enterprise integrating steel production and processing. Founded in 2011, the company is located in Liaocheng City,Shandong Province,China.

The company mainly produces: steel pipe,(seamless pipe,welded pipe) steel plate,steel bar,steel coil,steel strip,steel bar.

We have: stainless steel/carbon steel/iron/copper/aluminum/alloy steel/galvanized/chrome and other materials,our products meet the production standards,we provide polishing/bending/cutting/transportation services.

Support secondary processing,we have the most advanced equipment,support according to the drawing processing production.

The company always takes customer satisfaction as the service goal and provides customers with a full range of services.

Countries and regions around the world

Years of R&D

experience

Sets of products

Installation on

clients

Company has 13 years of experience with providing wide area of specialty services works listed below.

1. Structural seamless steel pipes (GB/T8162-2008) are seamless steel pipes used for general structures and mechanical structures. 2. Seamless steel pipes for fluid transportation (GB/T8163-2008) are general seamless steel pipes used to transport fluids such as water,oil,and gas. 3. Seamless steel pipes for low and medium pressure boilers (GB3087-2008) are used to manufacture superheated steam pipes for low and medium pressure boilers of various structures. High-quality carbon structural steel hot-rolled and cold-drawn (rolled) seamless steel pipes for boiling water pipes and superheated steam pipes for locomotive boilers,large smoke pipes,small smoke pipes and arch brick pipes. 4. Seamless steel pipes for high-pressure boilers (GB5310-2008) are high-quality carbon steel,alloy steel and stainless heat-resistant steel seamless steel pipes used for the heating surfaces of water tube boilers with high pressures and above. 5. High-pressure seamless steel pipes for fertilizer equipment (GB6479-2013) are high-quality carbon structural steel and alloy steel seamless steel pipes suitable for chemical equipment and pipelines with working temperatures of -40~400℃ and working pressures of 10~30Ma. 6. Seamless steel pipes for petroleum cracking (GB9948-2013) are seamless steel pipes suitable for furnace tubes,heat exchangers and pipelines in petroleum refineries. 7. Steel pipes for geological drilling (YB235-70) are steel pipes used by geological departments for core drilling. They can be divided into drill pipes,drill collars,core pipes,casings and sedimentation pipes according to their uses. 8. Seamless steel pipe for diamond core drilling (GB3423-82) is a seamless steel pipe used for drill pipe,core rod and casing for diamond core drilling. 9. Oil drilling pipe (YB528-65) is a seamless steel pipe with internal or external thickening at both ends used for oil drilling. There are two types of steel pipes: wired and unthreaded. Threaded pipes are connected with joints,while non-threaded pipes are connected with tool joints by butt welding. 10. Carbon steel seamless steel pipes for ships (GB/T5213-2009) are carbon steel seamless steel pipes used in manufacturing ships’ Class I pressure-resistant piping systems,Class II pressure-resistant piping systems,boilers and superheaters. The working temperature of the carbon steel seamless steel pipe wall does not exceed 450°C,and the working temperature of the alloy steel seamless steel pipe wall exceeds 450°C. 11. Seamless steel pipe for automobile half-shaft casing (GB3088-82) is a high-quality carbon structural steel and alloy structural steel hot-rolled seamless steel pipe used for manufacturing automobile half-shaft casings and drive axle housing shaft tubes. 12. High-pressure oil pipe for diesel engines (GB3093-2002) is a cold-drawn seamless steel pipe used to manufacture high-pressure pipes for diesel engine injection systems. 13. Precision inner diameter seamless steel pipe for hydraulic and pneumatic cylinders (GB8713-88) is a cold-drawn or cold-rolled precision seamless steel pipe with precise inner diameter for manufacturing hydraulic and pneumatic cylinders. 14. Cold-drawn or cold-rolled precision seamless steel pipe (GB3639-2000) is a cold-drawn or cold-rolled precision seamless steel pipe with high dimensional accuracy and good surface finish used in mechanical structures and hydraulic equipment. The use of precision seamless steel pipes to manufacture mechanical structures or hydraulic equipment can greatly save machining hours,improve material utilization,and at the same time help improve product quality. 15. Stainless steel seamless steel pipe for structural use (GB/T14975-2002) is a hot-rolled ( Extruded,expanded) and cold drawn (rolled) seamless steel pipes. 16. Stainless steel seamless steel pipes for fluid transportation (GB/T14976-2002) are hot-rolled (extruded,expanded) and cold-drawn (rolled) seamless steel pipes made of stainless steel used to transport fluids. 17. Special-shaped seamless steel pipe is a general term for seamless steel pipes with other cross-sectional shapes except round pipes. According to the different cross-sectional shape and size of the steel pipe,it can be divided into special-shaped seamless steel pipes with equal wall thickness (code-named D),special-shaped seamless steel pipes with unequal wall thickness (code-named BD) and variable-diameter special-shaped seamless steel pipes (code-named BJ). Special-shaped seamless steel pipes are widely used in various structural parts,tools and mechanical parts. Compared with round pipes,special-shaped pipes generally have a larger moment of inertia and section modulus,and have greater bending and torsion resistance,which can greatly reduce the weight of the structure and save steel.

High-quality carbon structural steel is carbon steel with a carbon content of less than 0.8%. This steel contains sulfur,phosphorus and non-toxic substances. It has fewer metal inclusions than carbon structural steel and has better mechanical properties. High-quality carbon structural steel can be divided into three categories according to different carbon contents: Low carbon steel (C≤0.25%),medium carbon steel (C 0.25-0.6%) and high carbon steel (C>0.6%). High-quality carbon structural steel is divided into normal manganese content (manganese content 0.25%-0.8%) and relatively high manganese content. There are two groups with high manganese content (manganese content 0.70%-1.20%),the latter has better mechanical properties and processing performance. High-quality carbon structural steel hot-rolled sheets and strips are used in the automotive,aerospace industry and other sectors. Its steel grades are low carbon steel including: 05F,08F,08,10F,10,15F,15,20F,20,25,20Mn,25Mn,etc.; Medium carbon steel includes: 30,35,40,45,50,55,60,30Mn,40Mn,50Mn,60Mn,etc.; High carbon steel includes: 65,70,65Mn,etc. Carbon steel is a common metal material with a wide range of application scenarios. 1. Construction and infrastructure: Carbon steel plays an important role in the construction and infrastructure fields. It is often used to make beams,columns,bridges,steel structures and other components because it has high strength,good plasticity and weldability,and can withstand complex mechanical loads and deformations. 2. Automobile industry: Carbon steel is one of the key materials in automobile manufacturing. It is widely used in automobile bodies,chassis,engine brackets,wheels and other components. Carbon steel has high strength,excellent impact toughness and plasticity,providing the safety and reliability needed for vehicles. 3. Mechanical equipment: Carbon steel is widely used in the field of mechanical equipment manufacturing. It can be used to manufacture various parts and components,such as bearings,gears,connectors,etc. Carbon steel has good cutting performance and wear resistance,and is suitable for use in high-speed moving parts and high-load working environments. 4. Manufacturing: Carbon steel is used in various manufacturing industries. For example,it is used in the manufacture of appliances,tools,pipes,boilers,and containers,among others. Carbon steel has good plasticity and welding properties,and can meet the requirements of different industries for material strength and processing performance. 5. Energy industry: Carbon steel plays an important role in the energy industry. It is commonly used in oil and gas pipelines,power generation equipment,nuclear power plant structures,etc. Carbon steel has high temperature resistance and corrosion resistance,and can adapt to complex working environments. All in all,the main application scenarios of carbon steel include construction and infrastructure,automotive industry,machinery and equipment,manufacturing and energy industries. Its excellent properties make carbon steel one of the indispensable materials in many fields.

Shandong Jiate Steel Co.,Ltd. is an enterprise integrating steel production and processing. Support secondary processing,we have the most advanced equipment,support according to the drawing processing production. The company always takes customer satisfaction as the service goal and provides customers with a full range of services.

In recent years,our company has participated in many do mestic international steel exhibitions. As an exhibitor,we have a lot of exposure at the exhibition. Our friends come from all over the world.

Our company is mainly engaged in import and export trade. In recent years,the number of export orders has been large and the number has increased. Our customers and friends come from all over the world and are domestic high - quality steel suppliers.

At the beginning of our establishment,our company focused on domestic trade and had a large number of stable customers in the country. Not only did it develop rapidly in the foreign trade industry,but also the domestic trade was steadily increasing.

Our clients come from all over the world and have maintained long-term cooperation. We have worked with customers in more than 30 countries in Europe. Southeast Asia. Africa and Asia.