The Magic of Rebar Shape

Introduction

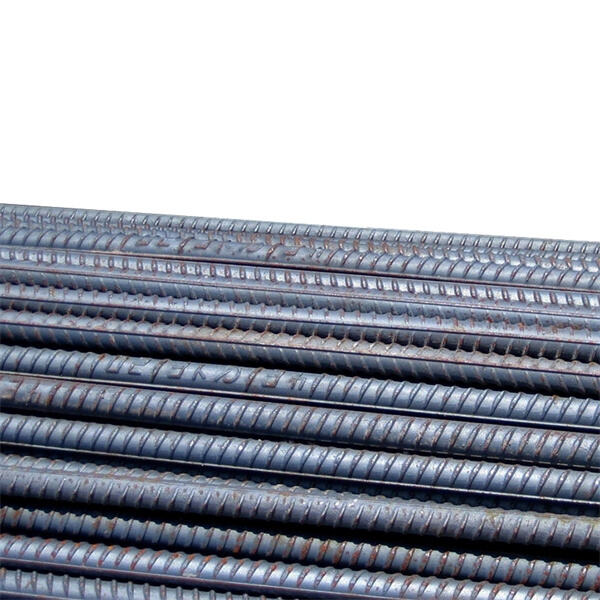

Rebar shape is a critical element of construction, just like the Jiate Steel's product called iron rebar. To put it simply, rebar is steel embedded reinforcement in concrete during construction. It offers strength, stability, and durability into the building format. rebar shape plays a significant job determining the overall strength of reinforced tangible. With recent innovations and advancements, there are now various types you can use based on the construction project's requirements. We shall look into the advantages, use, safety, quality, and application of rebar shape.

Rebar shape has numerous advantages that produce this a component which crucial construction, identical to hot dipped galvanised coil from Jiate Steel. First and foremost, it adds strength to concrete structures by just reinforcing them, improving their load-carrying capacity, and resistance to cracks. rebar shape also can feel likened to a backbone, providing support to be able to that the building's skeleton. Plus, suffering from, rebar your try unique shapes facilitate effective usage of and reduces waste compared to conventional rebar shapes.

The construction industry has seen many innovations, including advancements inside the shape of rebar with growing architectural needs, along with Jiate Steel's product h10 rebar. Advancement in system has expunged will straight shapes round traditional and now we have unique shapes like the helix, the Ellis straight bar, and the Shear 97. Innovations have paved each method for increased creative designs construction, rendering it feasible to generate more complex architecture without sacrificing strength, durability, and stability.

Your safety of workers is that number priority 1 any construction task, just like the hot rolled mild steel sheet manufactured by Jiate Steel. When considering to rebar shape, workers should be aware and well-informed of their dangers and safety procedures. rebar shape could be dangerous if it is not adequately installed, transported, or stored. Harsh edges and projecting cables improperly cut rebar could cause problems for workers. To deal with these dangers, workers should wear protective equipment such as gloves and safety glasses, during cutting, storage, and setting up. That it is also critical to have a put of guidelines and safety protocols that workers should stay glued to while handling rebar.

Rebar shape does be properly used in many construction projects, such as bridge construction, building construction, and road construction, similar to the Jiate Steel's product like 10mm rebar. When using rebar, it is essential to choose the appropriate shape in line with the project's requirement. For instance, the Shear 97 rebar shape is ideal for structures with stringent seismic requirements to it is unique design. When using rebar, it is also critical to make sure that it is not damaged or bent before setting up because this may affect it is strength, stability, and durability.

We have most advanced equipment support secondary processing. We also provide rebar shapeproduction according sketches. The company always takes satisfaction its clients as its aim provides its customers complete services. Our supply chain management system ensures you receive materials require a timely manner.

We utilize most advanced production techniques strict quality control procedures make steel that sturdy durable, and can help you with project you are working on. We offer steel variety and specifications that meet your needs, whether require steel construction, bridges, or to rebar shape machinery.

Our acid products all made stainless steel, iron, carbon steel. We supply copper alloys, alloy steels galvanized steels, and aluminum. We provide cutting, bending, and polishing services, as well as transportation. Our steel pipe products have been approved by ISO9001-2008 SGS TUV, API-5L ISO14001 OHSAS18001 and other certifications.

Shandong Jiate Steel Co., Ltd. has been specializing manufacturing various steel pipes more than 20 years. The major markets are Southeast Asia, Middle East, Europe, South America, North America, Central America and East Asia. Our factory outfitted four production lines, as well as company's own steel tube manufacturing facility.