The steel is put into a clean furnace. This furnace is extremely hot and used to heat the steel until it glows slightly. This process is called annealing. The importance of annealing is that it causes the steel to soften. In an ideal world, softer steel is also easier to work with and coat. During the galvanizing process of steel by Jiate Steel, this thin zinc layer will melt and mix with molten liquid steel; thus, on solidification have a composition similar to other steels also formatting in surface.

Tips On Making Galvalvanized Coils

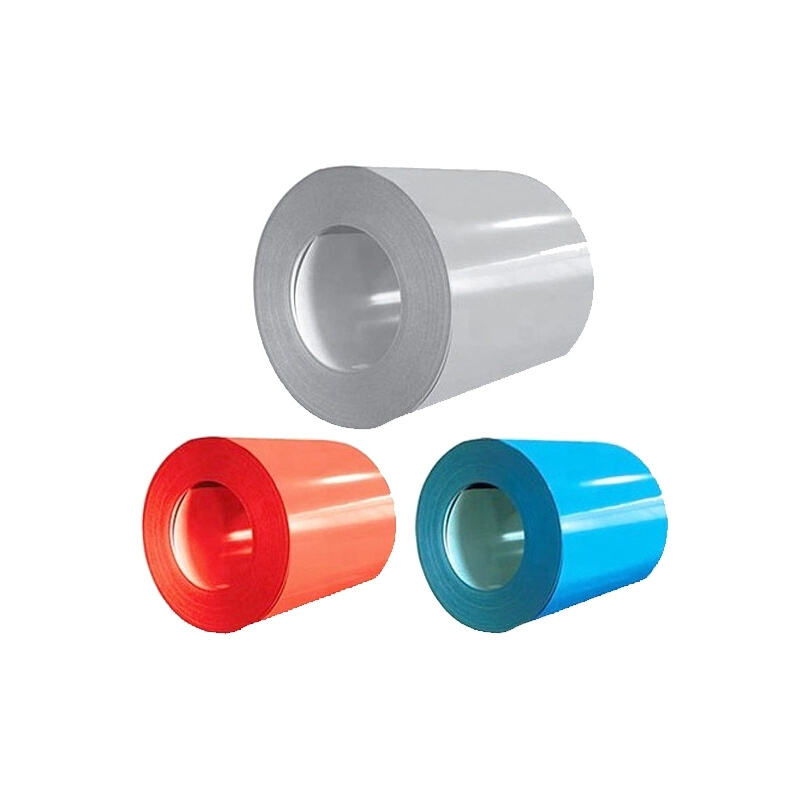

After the cold sheet of steel has gone through an annealing furnace and is hot, it then gets coated with a layer of zinc. Then, the flat stainless sheet is immersed into a molten zinc bath. The process of adding layer of zinc is called galvanization, which we detailed in our corrosion you are more than welcome to check out. The zinc is what creates a strong protective layer over the steel that stays off from corrosion and other types of damage. After getting the sheet with a zinc coating on each side, it cools and solidifies. The coated sheet is finally unrolled again and then it can be used in the manufacturing of many other products.

Some Good Practice while Making Galvanized Coils

The standard quality of the galvanized coils is maintained by taking care that more than required thickness does not get coated with zinc. When coverage is thin, the metal plating can corrode very rapidly. Thicker ones can also cost more to produce. When that is the case, you should use a good quality zinc and control coating temperature and line speed to maintain correct level thickness. Apart from this, the correct cleaning of steel sheet before coating is also important. Dirt residue remaining on the plate can result in flaws of grammar to appear in its print. Therefore, in this situation proper cleaning is necessary to keep office clean. In order to make the galvanized coil correctly some good practices need to be maintained during well that manufacturing process.

Adopting Strategy to Manufacture Galvanized Coils:

One of the widely accepted practices, when it comes too manufacturing galvanized coils involves investing in advanced machines and technology. For example, it is extremely important to use the best furnaces and coating equipment you can get your hands on as well as corny systems that check automatic this production process quality. This is a big factor in the final product. An additional fantastic practice for creating galvanized coils is to have excellent workers. The production of galvanized steel coil requires expertise in a variety of fields such as metalworking, chemistry, and engineering. An expert team can easily identify issue if the same appears in production phase. This reduces downtime, and guarantees the highest quality end product.

Top Insights For Producing High-Quality Galvanized Coils

The process of making galvanized coils is rigorous, which means that attention and work have to be given in each step. Manufacturers can produce coils that last a long time and provide effective rust protection with the help of good practices, expert tips as well as an invested workforce. This dedication has resulted in the highest quality coils and greatest defense against corrosion.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

BE

BE

AZ

AZ

LO

LO

MN

MN

MY

MY

KK

KK

SU

SU

UZ

UZ

KY

KY