Carbon steel seamless pipe

Carbon steel seamless steel pipe is a type of long strip steel.

Steel pipes have a hollow cross-section and are widely used as pipelines for transporting fluids, such as oil, natural gas, gas, water, and certain solid materials.

Compared with solid steel such as round steel, steel pipes have the same flexural and torsional strength while also being lighter in weight. They are an economical cross-section steel and are widely used in the manufacturing of structural and mechanical components, such as petroleum drill pipes, automotive transmission shafts, bicycle frames, and steel scaffolding used in construction.

Production process:

① The main production processes (main inspection processes) of hot-rolled seamless steel pipes:

Pipe blank preparation and inspection → Pipe blank heating → Piercing → Rolling → Reheating of raw pipes → Sizing (reducing) → Heat treatment→ Straightening of finished pipes → Finishing → Inspection (non-destructive, physical and chemical, machine inspection) → Warehousing

② The main production process of cold rolled (drawn) seamless steel pipes: blank preparation → acid washing and lubrication → cold rolling (drawing) → heat treatment → straightening → finishing → inspection

Manufacturing circular parts using steel pipes can improve material utilization, simplify manufacturing processes, save materials and processing time, such as rolling bearing rings, jack sleeves, etc. Currently, steel pipes are widely used for manufacturing.

Steel pipes are also an indispensable material for various conventional weapons, and they are used to manufacture gun barrels and barrels. Steel pipes can be divided into circular pipes and irregular pipes according to their cross-sectional area and shape. Due to the fact that under the condition of equal circumference, the circular area is the largest, and circular pipes can transport more fluid. In addition, when the circular ring section is subjected to internal or external radial pressure, the force is relatively uniform, therefore, the vast majority of steel pipes are circular pipes.

Manufacturing circular parts using steel pipes can improve material utilization, simplify manufacturing processes, save materials and processing time, such as rolling bearing rings, jack sleeves, etc. Currently, steel pipes are widely used for manufacturing.

It is divided into 10 # seamless steel pipes, 20 # seamless steel pipes, 45 # seamless steel pipes, etc.

Recommended Products

Hot News

-

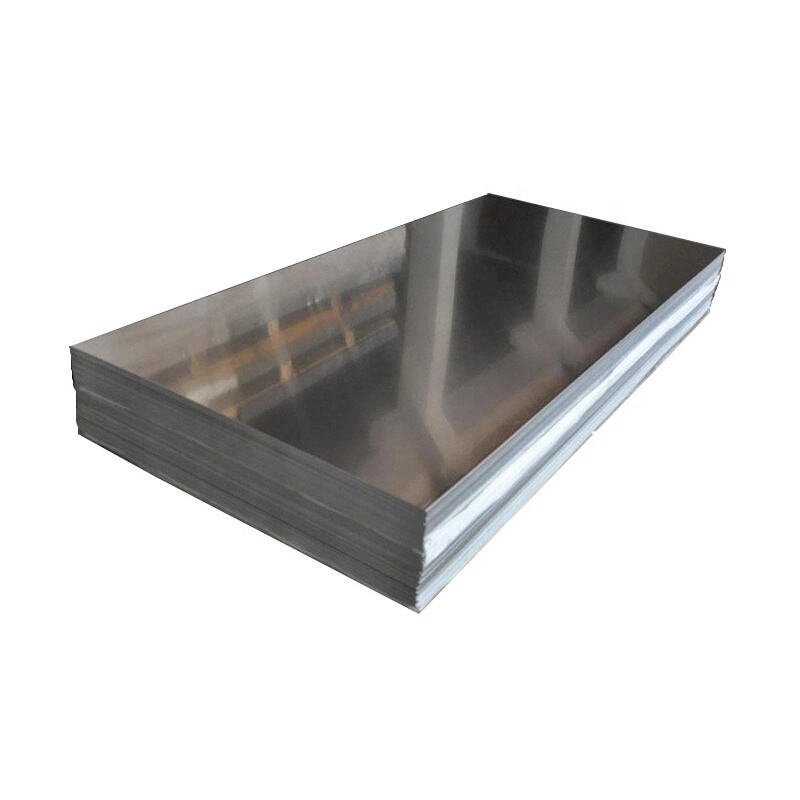

Stainless steel plate

2023-10-17

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

BE

BE

AZ

AZ

LO

LO

MN

MN

MY

MY

KK

KK

SU

SU

UZ

UZ

KY

KY