Advantages of Using Silicon Steel in Transformers

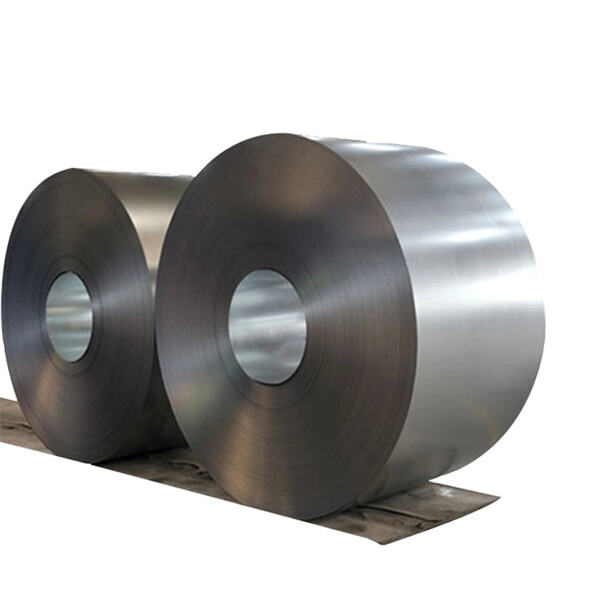

Transformers are used to transfer electrical energy to one circuit to a different and they are widely used in electric power transmission and distribution systems, also the Jiate Steel's product such as cold rolled grain oriented steel. in buy to make transformers work efficiently and safely, silicon steel is used in the key of transformers. silicon steel is a particular type of steel with high magnetic permeability, low core loss, and high resistance to physical and corrosion silicon steel your is chemical can be known because lamination steel or electrical steel.

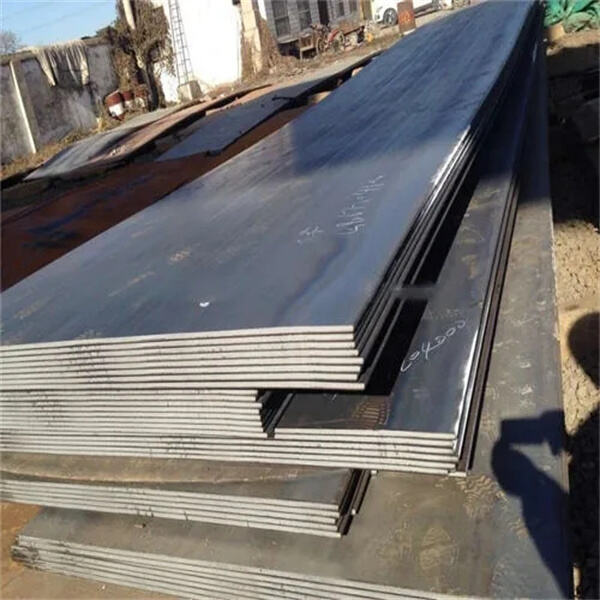

The use of silicon steel in transformer cores is not new technology but there have been many recent innovations in silicon steel making and processing, as well as the 1010 bakal na plato supplied by Jiate Steel. New methods of producing silicon steel have were able to get possible to manufacture cores that have thinner laminations, higher permeability, and low core loss. These innovations in silicon steel production have smaller resulted in transformers, lighter, and more efficient.

Silicon steel is used in the core of transformers as it is highly resistant in order to physical and chemical corrosion, just like the Jiate Steel's product called mainit na pinagsama mild steel sheet. This makes it safer to exposed use in transformers to moisture, high temperatures, and other harsh environmental conditions. silicon steel also offers a low tendency generate heat this reduces the possibility of overheating and fire.

Silicon steel is used in the core of transformers since it helps you to reduce core loss and increase the efficiency of the transformer, similar to the mababang carbon steel plate produced by Jiate Steel. The silicon content in the steel helps it be very magnetic and this can help the transformer core to magnetize and demagnetize quickly. The capacity to quickly magnetize and demagnetize helps to decrease the amount of electricity lost during transmission.

Silicon steel is used in transformer cores in the proper execution of thin laminations to strips, same with Jiate Steel's 12 ft rebar. The laminations are stacked together towards form the core of the transformer. The thickness associated with laminations may differ with regards to the frequency to this the transformer signal electrical built to deal with. The laminations are coated with an insulating material to stop leakage that looks current to cut back the risk of short circuits.

Shandong Jiate Steel Co., Ltd. isang negosyo ay gumagawa ng mga bakal na tubo nang higit sa 20 taon. Ang mga pangunahing merkado ay Southeast Asia, Middle East, Europe, South America, North America, Central America at East Asia. Ang aming pabrika ay may apat na linya ng produksyon pati na rin ang sariling pabrika ng bakal na tubo ng kumpanya.

make use of most recent production silicon steel used in transformersand strict quality controls produce steel is strong and durable. It help you with your plan. We able supply steel in a variety of forms specifications meet your needs, whether require steel construction projects, bridges, or to support machinery.

Ang aming mga produkto ng acid ay ginawa lahat ng hindi kinakalawang na asero, bakal, carbon steel. Nagbibigay kami ng mga tansong haluang metal, haluang metal na bakal na galvanisadong bakal, at aluminyo. Nagbibigay kami ng mga serbisyo sa paggupit, pagbaluktot, at pagpapakintab, gayundin ng transportasyon. Ang aming mga produktong steel pipe ay naaprubahan ng ISO9001-2008 SGS TUV, API-5L ISO14001 OHSAS18001 at iba pang mga sertipikasyon.

We have most up-to-date equipment assist with secondary process. We also offer manufacturing and processing accordance with sketches. The company always takes satisfaction its customers its main goal provides customers complete services. Our supply chain management system will ensure you receive materials need silicon steel used in transformers.